When it comes to handling complex and sensitive materials in industrial processes, progressing cavity pumps stand out as indispensable tools. From their design to their functionality, these pumps have found their place in a wide range of industries, proving their value time and time again. Let’s explore the unique capabilities of progressing cavity pumps and understand why they are crucial in certain applications, including their specialized role as chocolate pumps.

What Are Progressing Cavity Pumps?

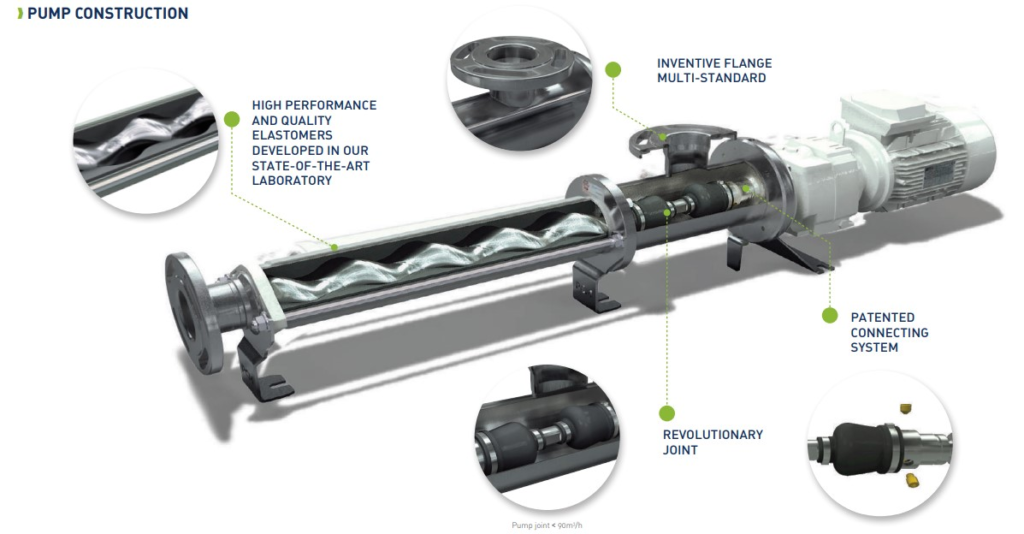

Progressing cavity pumps are positive displacement pumps that work by moving fluids through a sequence of small, fixed cavities. A rotor rotates within a stator, creating a continuous flow of liquid. This design is particularly effective for handling viscous, abrasive, or shear-sensitive materials, which might pose challenges for other types of pumps.

Key Features of Progressing Cavity Pumps:

- Consistent Flow: They provide a smooth and uninterrupted flow, regardless of the viscosity of the material being pumped.

- Shear Sensitivity: Ideal for fragile substances, these pumps minimize damage to the material.

- Versatility: Suitable for a variety of liquids, including those with solids, abrasives, or high viscosities.

Applications of Progressing Cavity Pumps

One of the reasons progressing cavity pumps are highly regarded is their versatility. They are employed in numerous industries, ranging from wastewater treatment to food production. Below are some specific applications:

- Food and Beverage Industry: In the production of items like syrups, yogurt, and even chocolate, progressing cavity pumps excel. When functioning as chocolate pumps, they ensure the careful handling of molten chocolate, preserving its texture and quality while delivering consistent flow.

- Oil and Gas: These pumps handle crude oil, drilling muds, and other challenging substances, showcasing their ability to manage materials with varying viscosities.

- Wastewater Treatment: Progressing cavity pumps are critical for moving sludge, slurry, and other thick liquids in wastewater treatment facilities.

- Pharmaceuticals: Their ability to handle shear-sensitive materials makes them perfect for producing creams, gels, and other pharmaceutical products.

Why Choose Progressing Cavity Pumps?

The design and operation of progressing cavity pumps provide distinct advantages over other pump types. Here are some reasons why industries prefer them:

- Efficiency in High Viscosity Applications: Progressing cavity pumps can handle extremely viscous fluids, making them the go-to choice for tasks such as moving heavy oils or thick slurries.

- Low Maintenance Requirements: With proper care, these pumps have a long service life, reducing downtime and operational costs.

- Customizability: These pumps can be tailored to specific industrial needs, such as temperature control when used as chocolate pumps in confectionery production.

Chocolate Pumps: A Sweet Application

When discussing the specific role of progressing cavity pumps in the food industry, their use as chocolate pumps deserves special mention. Handling molten chocolate requires precision and care, as any disruption in flow or excessive shear can affect the quality of the final product. Progressing cavity pumps ensure:

- Temperature Stability: Maintaining the correct temperature to keep chocolate in a liquid state.

- Gentle Handling: Preventing the formation of air bubbles or changes in texture.

- Precise Delivery: Ensuring consistent flow rates for molding, enrobing, or mixing processes.

Maintenance and Best Practices

To maximize the lifespan and efficiency of progressing cavity pumps, proper maintenance is essential. Here are some tips:

- Regular Inspection: Check for wear and tear on the rotor and stator.

- Cleaning: Ensure thorough cleaning, especially when handling food-grade materials like chocolate.

- Lubrication: Keep moving parts well-lubricated to minimize friction and wear.

- Timely Repairs: Address minor issues promptly to avoid costly repairs later.

The Future of Progressing Cavity Pumps

As industries evolve, so do the demands placed on equipment. Progressing cavity pumps are no exception. Innovations are being developed to improve their efficiency, durability, and environmental impact. For instance:

- Advanced Materials: The use of more robust and corrosion-resistant materials enhances pump longevity.

- Energy Efficiency: Modern designs focus on reducing energy consumption without compromising performance.

- Automation Integration: Smart technology enables better monitoring and control of pump operations, reducing manual intervention.

Progressing cavity pumps are a testament to engineering ingenuity, offering unmatched versatility and reliability across various industries. Whether in wastewater treatment plants or as chocolate pumps in confectionery factories, these pumps play a vital role in ensuring smooth and efficient operations. Their ability to handle challenging materials with care and precision makes them indispensable tools in today’s industrial landscape. With continuous advancements, the future looks bright for progressing cavity pumps, promising even greater contributions to diverse fields.